Showcase: Motor City Aftermarket Components & CAT Toolbox

GOOD DESIGN GETS TO WORK

Design Eye Q worked with Motor City Aftermarket, official licensee of Cat® work truck products.

Back in 2017, we were in Michigan doing some promotional work when we ran into a representative from Motor City Aftermarket, a badass Detroit company making aftermarket Jeep components. Impressed with our work on the Exodus machine, Motor City Aftermarket decided to hire us to design some of their components.

Make it stand out

Motor City Aftermarket has done incredible work identifying and engaging their target audience. The people buying their components want high-quality, hard-working products for going off-road.

The company works closely with a defense supplier, so the same tools that produced parts for the Abrams tank are used to cut, fold and weld their components, imbuing the parts with what they call “Tank DNA”. That’s a powerful market differentiator.

Make it stand out

Working with Motor City, we made pickup truck parts and Jeep parts. Our aim was to make these components lease-friendly (meaning they could be removed without harming the vehicle, or without being welded into place) and incredibly tough. Some of these components were geared towards competition Jeeps, the kind of off-road gladiators you would find at the King of the Hammers Race. The components had to be absolutely premium quality to hold up under that kind of stress. We designed things like headache racks, roof racks, and bed storage systems with partitions.

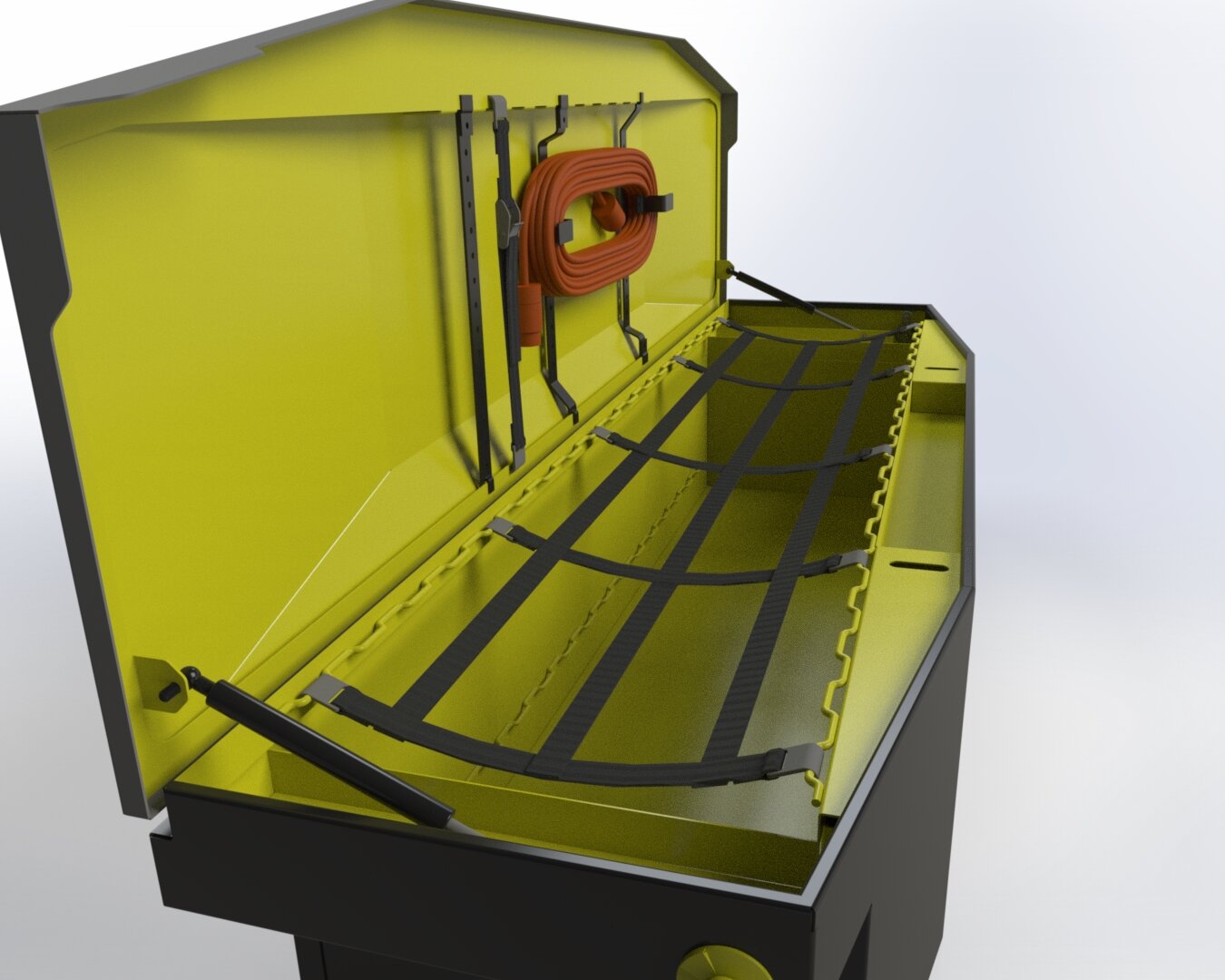

At SEMA in 2018, Motor City Aftermarket connected with CAT. CAT was interested in producing a premium truck component: something you could sell to a Ford 150 owner who wanted to rep the CAT brand. Working closely with Motor City, we designed this truck bed toolbox.

This tool box is much more than a sweet piece of truck jewelry. The lid is something special: architectural, with a diamond-plated weather guard. Inside, Motor City included footman loops, which are ubiquitous on military vehicles (remember the “Tank DNA” we mentioned earlier? Motor City is on point).

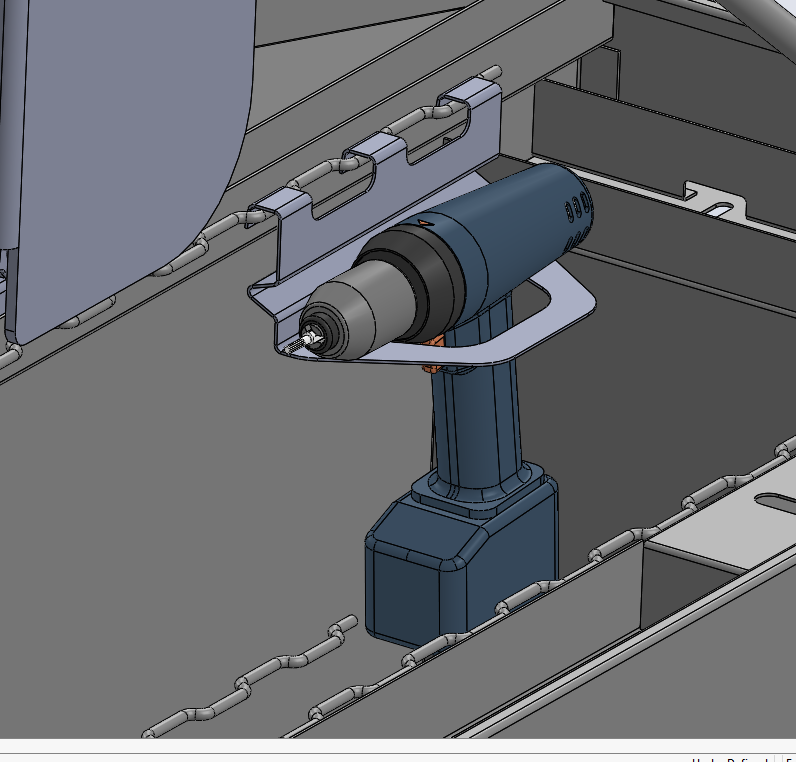

We designed strategic partitions for everything from fishing poles to shotguns. We even created a charging apparatus with 120 volt outlets, so you could transport and charge a few batteries.

We also wanted to ensure that the toolbox was secure. On a construction site, it’s not uncommon for tools to get stolen from beds and boxes. We designed our box with a dual-lock, dual-latch system.

The dual locks make it virtually impossible to pry open. The dual latches make it more convenient for the owner, as the box can be opened or closed from just one side of the truck, without having to walk around the bed or hop inside. We also worked closely with strut manufacturers to find precisely the right strut, so that the box would close on it’s own if you pushed the lid down far enough.

It is truly a premium component, worthy of the CAT brand. The average truck bed toolbox that you buy at the hardware store just doesn’t compare.

As for the design process, we have to give Solidworks some credit for their Sheet Metal Design Module. It allowed us to design both folded and unfolded units, which was really handy. We also used the Solidworks PDM system to do configuration management. That meant we could reconfigure a base box model to fit different specs. We like to give Solidworks a hard time, but those two modules worked great for this project.