What is CAS (Computer Aided Styling) and why does it matter

What is CAS (Computer Aided Styling)

and Why Does it Matter?

Computer-aided styling (known as CAS or digital sculpting) is concerned primarily with Class A surfaces, or the stylized surfaces that users can see and touch. These are some of the most highly scrutinized CAD surfaces and require both tools and skills not typical of product design. You need to be sensitive to both the designer's intent (because some of the time you're not the original designer) and the engineering requirements.

Make it stand out

Many of the most successful designers will employ NURBS and Bezier-based CAS (computer-aided styling) tools. Creating a CAS design is essentially translating an industrial designer’s intention into usable data. You've done well if your model looks expressive (as the artist intended) and engineering also likes it.

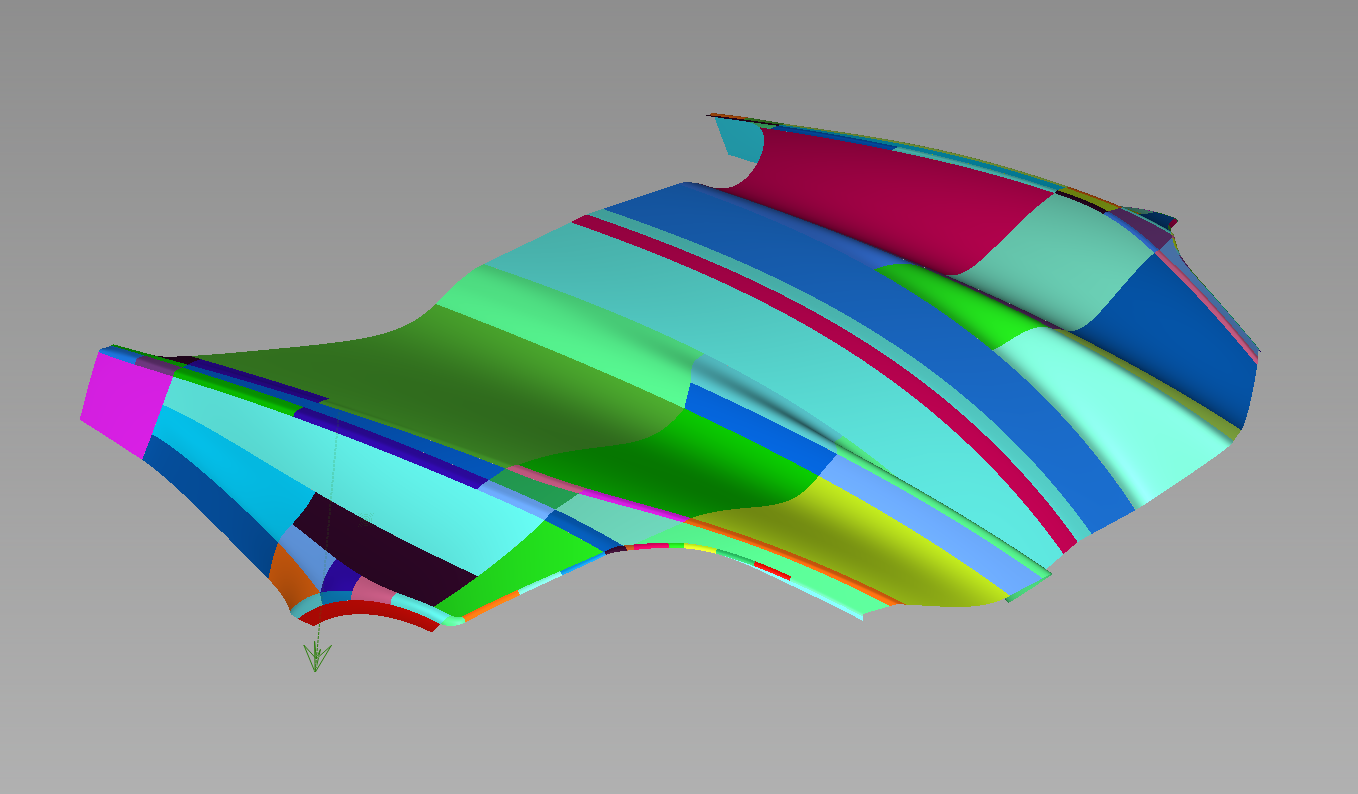

This process can begin with a sketch, CAD model, or physical model. When our studio designed this Camaro Class A re-body, we started with a CAD model, sketched our intentions over the car, removed the body parts that changed, then sculpted our own custom parts.

Why does CAS matter in product design?

There is a big difference between a model and a sculpture. The primary intent behind block modeling is precision; the primary intent behind 3D sculpting is elegance. Imagine walking into an auto show and seeing a new Ferrari -- those feelings of awe and (dare we say) reverence are the direct result of CAS design.

Quality CAS modeling techniques include:

EFFICIENT PATCH LAYOUT

Elegance is often ingeniously simple. Surfacers understand what is being asked of the sculpture and how to get there without excessive surfaces, trims or features. In other words, less is more.

CONTROLLED CURVATURE CONTINUITY

Our eyes are drawn around a sculpture by interpreting value and reflection changes. CAS tool-set can visually display concave and convex curvature. This allows shadow lines and reflections to appear straight and intentional.

GRACEFUL AND SMOOTH DESIGN

Zebra stripe analysis is another way to evaluate surface quality and continuity. This technique simulates an exaggerated striped reflective pattern across the surface network, so you can easily spot undesirable distortions and tears. It makes tidying things up a lot easier.

VISUALIZATION

One of the most satisfying CAS tools is the product visualization tool. The surface is placed in a realistic environment and allowed to pick up natural reflections. You can choose between any number of locations -- outside, in a warehouse, etc. -- and preview how the surface will appear.

COMPATIBILITY

CAS designers are not the last technicians to work with a product. Quite often your CAS surface will be thickened into a part, turned into tooling, or 3D printed. CAS models need to be compatible with the leading CAD and CAM software suites.

Want to take a closer look at this file? Sign up for our Newsletter, and get this CAD file in a STEP format.

How do you go about CAS design?

Designing something perfectly proportioned, nuanced, and evocative is not easy, and it’s certainly not possible using block modeling software like Solidworks. Block modelers aren’t going to “make a guess” or help translate an artist’s sketch into something producible. CAS design requires sophisticated software such as Autodesk Alias, Catia V5, or ICEM Surf. With these tools, a skilled designer can create a sculpture that not only captures the artistic intent, but can be easily converted to an engineering software like Solidworks.

Our studio particularly enjoys CAS design. Our experience working closely among engineers in the aerospace industry (a job that requires absolute precision), combined with our bespoke designs makes us uniquely qualified for 3D sculpting.